Welcome to ProTool Thailand, where we delve into the world of precision measurement tools. In this article, we will explore the fascinating and versatile realm of plain plug gauges. These essential tools are widely used in industries ranging from manufacturing and engineering to quality control and inspection. Let’s dive into the significance of plain plug gauges and how they play a crucial role in ensuring accuracy and consistency in various applications.

Understanding Plain Plug Gauges

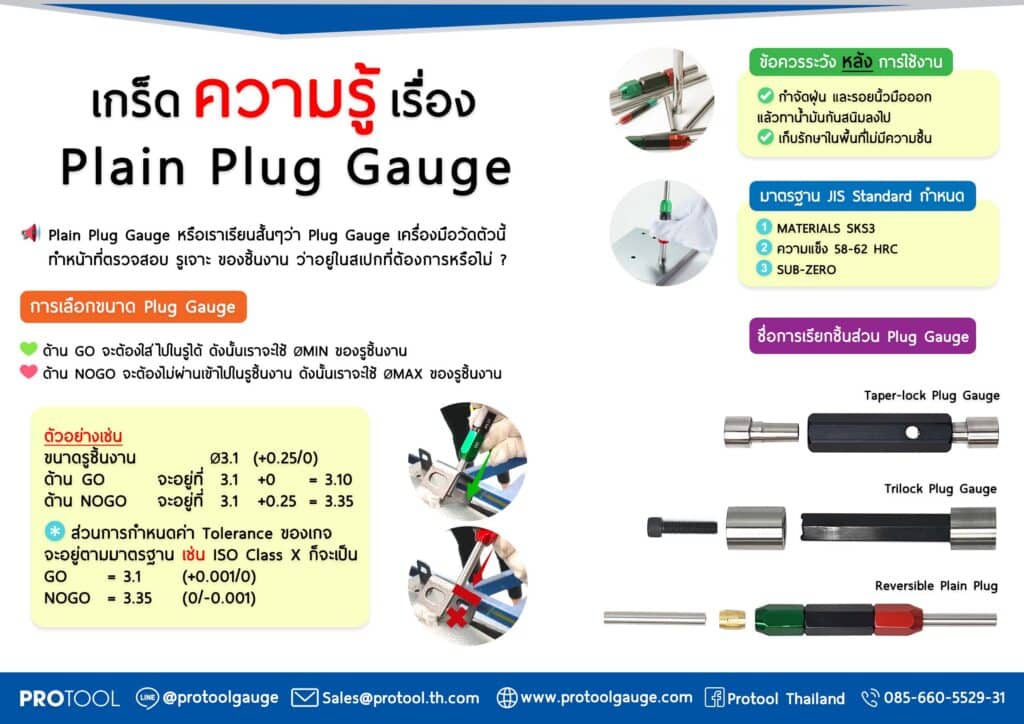

Plain plug gauges, also known as plug gauges or pin gauges, are cylindrical tools used to check the size and accuracy of holes and bores in workpieces. They consist of a cylindrical body with two functional ends: the “go” end and the “no-go” end. The go end is designed to check the lower tolerance limit of the hole, ensuring it is not too small, while the no-go end checks the upper tolerance limit, ensuring it is not too large.

How Plain Plug Gauges Work

When performing an inspection with a plain plug gauge, the go end should fully enter the hole if the dimensions are within the acceptable tolerance range. Conversely, the no-go end should not fit into the hole if the bore size exceeds the upper tolerance limit. The precision and accuracy of these gauges are crucial for verifying the compliance of the workpiece with predetermined specifications.

Applications of Plain Plug Gauge

Plain plug gauges find extensive use in various industries for inspecting and verifying the dimensional accuracy of cylindrical components. Some common applications include:

- Manufacturing: In the production of machined parts and components, plug gauges are employed to ensure the holes meet the required specifications, thus guaranteeing proper fit and assembly.

- Automotive Industry: Plug gauge are utilized to check critical engine components like cylinder bores, ensuring they meet strict tolerances for optimal performance and efficiency.

- Aerospace: In aerospace engineering, precision is paramount. Plain plug gauges are used to verify the accuracy of aircraft components, guaranteeing safety and reliability.

- Medical Devices: In the production of medical equipment and implants, plug gauge play a vital role in maintaining the required standards for patient safety.

Advantages of Plain Plug Gauge

- Quick and Simple: Using plain plug gauge is a straightforward process, allowing for rapid inspections, which enhances productivity.

- Cost-Effective: These gauges are a cost-effective solution for ensuring quality control during the manufacturing process.

- Repeatable Accuracy: High-quality plain plug gauge provide reliable and repeatable measurements, reducing the likelihood of errors.

Conclusion

Plain plug gauge are indispensable tools for ensuring the precision and consistency of cylindrical components in various industries. ProTool Thailand offers a wide range of reliable and accurate plain plug gauges, helping businesses maintain quality control and meet stringent industry standards. With these essential instruments, manufacturers and engineers can have confidence in the accuracy of their products, ultimately leading to improved performance and customer satisfaction.