Checking Runout Crankshaft with Laser Marking

Checking Runout Crankshaft with Laser Marking

Categories AUTOMATION, SPECIAL AUTOMATION

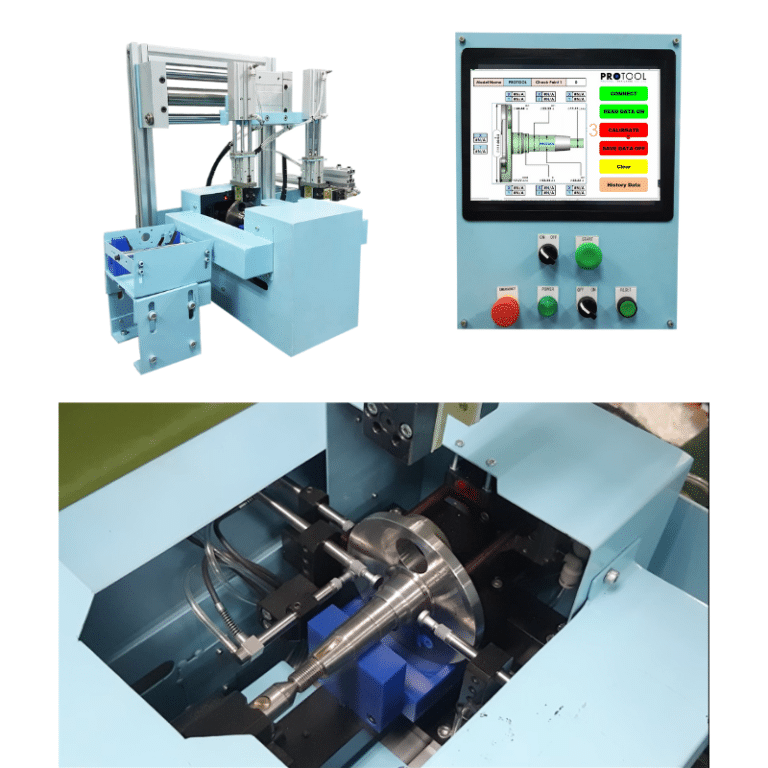

Checking Runout Crankshaft with Laser Marking

Checking the runout of a crankshaft is a crucial step in the manufacturing and maintenance process of engines. It significantly affects the performance and lifespan of the engine. Utilizing laser marking technology in this process enhances precision and speed of inspection.

Benefits of Using Laser Marking for Checking Crankshaft Runout

- High Precision:

- Laser marking can measure and record data with high accuracy, enabling the detection of deviations or abnormalities in detail.

- Fast Process:

- The use of laser marking reduces the time required to check the crankshaft runout compared to traditional methods.

- Automatic Data Recording:

- The laser marking system can automatically record inspection data into a computer system, making it easy to store and analyze data later.

- High Safety:

- Using lasers reduces the risk associated with using mechanical tools that might cause damage or injury to the operator.

Process of Checking Crankshaft Runout with Laser Marking

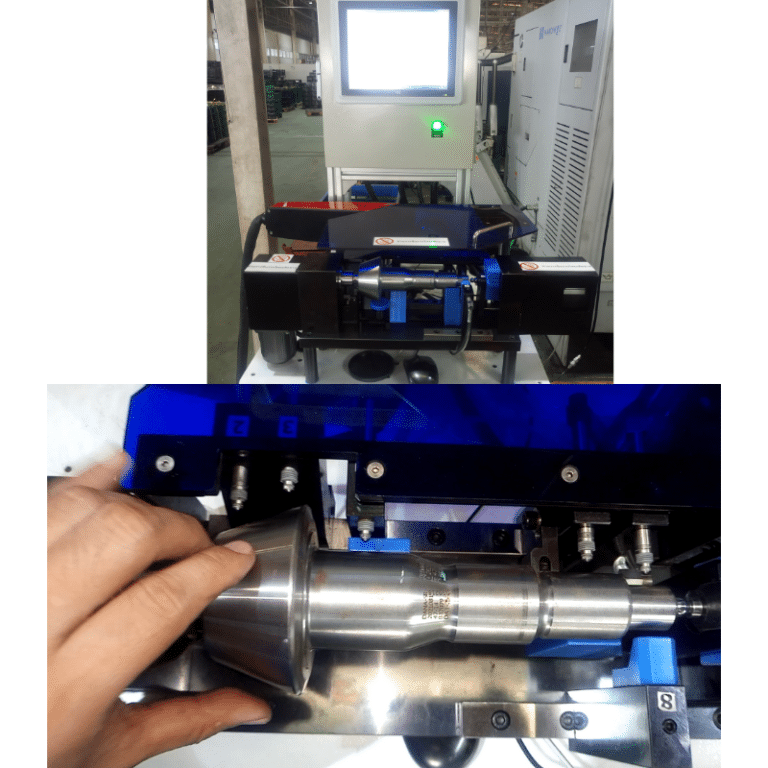

- Preparing the Crankshaft:

- Clean the crankshaft to ensure there is no dirt or oil residue that could interfere with the inspection.

- Setting Up the Laser Marking Machine:

- Configure the laser machine to match the size and type of crankshaft to be inspected.

- Measuring Runout:

- Use the laser to measure the crankshaft runout by rotating the crankshaft and checking the deviation of the diameter at each point.

- The obtained data will be recorded and displayed on the computer screen.

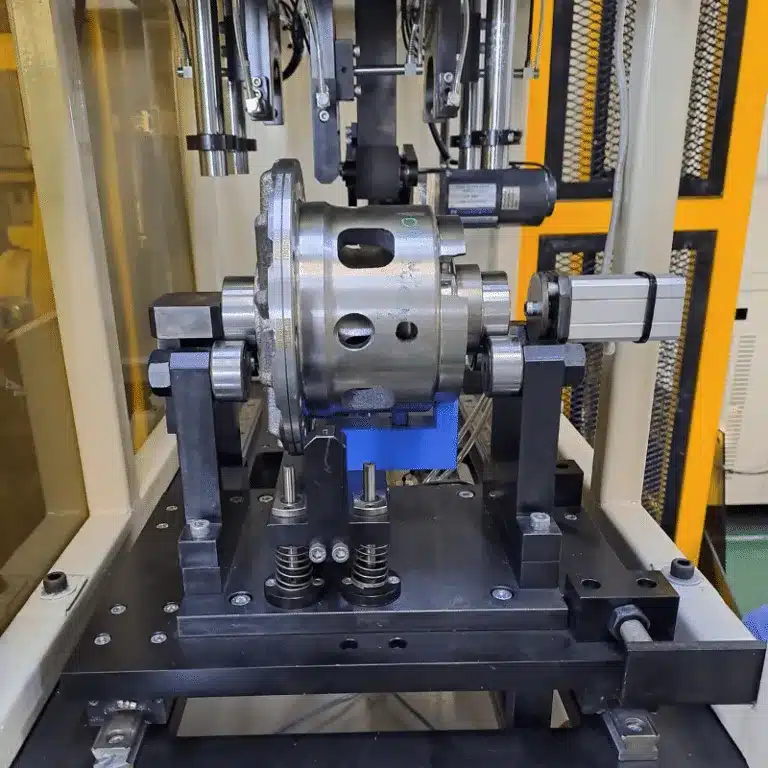

- Data Analysis:

- Analyze the runout data obtained from the inspection to determine deviations that might affect engine performance.

- Laser Marking:

- If deviations exceeding the standards are found, laser marking can be used to mark the points that need correction on the crankshaft immediately.

Contact Us

Other Products

CR Series

The CR series is cobot flagship line of industrial collaborative robots with 3 kg to 16kg...

CR Series Collaborative Robots

CR Series Collaborative Robots consists of 6 payloads: 3 kg, 5 kg, 7...

Nova Series Collaborative Robot

The Nova Series robots are available with payload options up to 2kg...

"Following thorough measurement and quality inspection, the most effective

means to distinguish good...

"In addition to its exceptional measurement capabilities, our machine

boasts impressive positioning...

"Our new automated dimensional measurement machine represents

a leap into the latest frontier of technology....

"Introducing our user-friendly camera inspection system, designed

to seamlessly take over quality inspections,...

"Our machines go beyond dimensional measurements.

We incorporate cutting-edge dynamic sensors, temperature...

"Our machine offers a versatile combination of sophisticated

geometric measurements, enhanced by our...

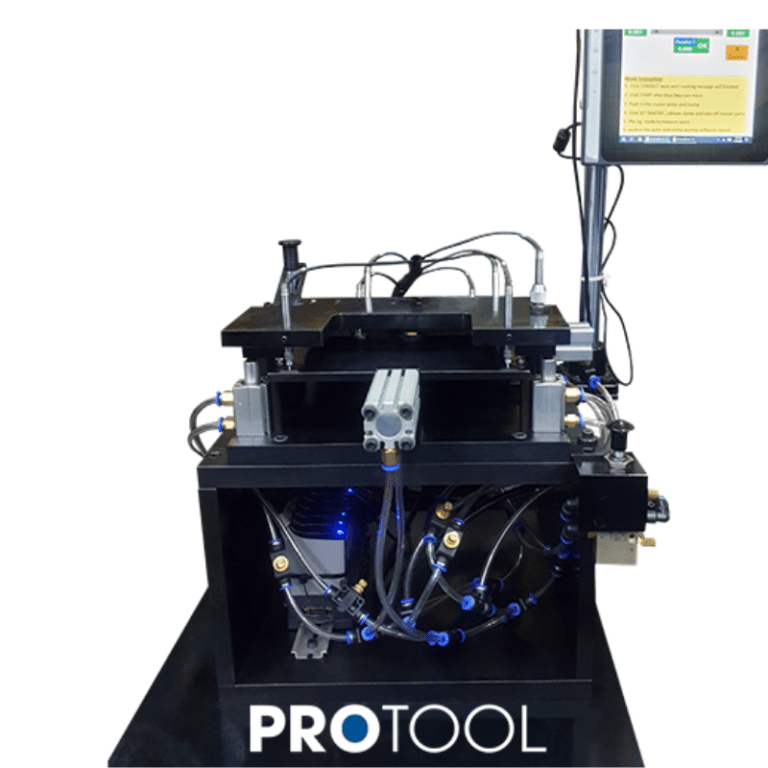

“Protool specialize in the comprehensive design and

construction of Automatic Measuring Machines in...

No products found