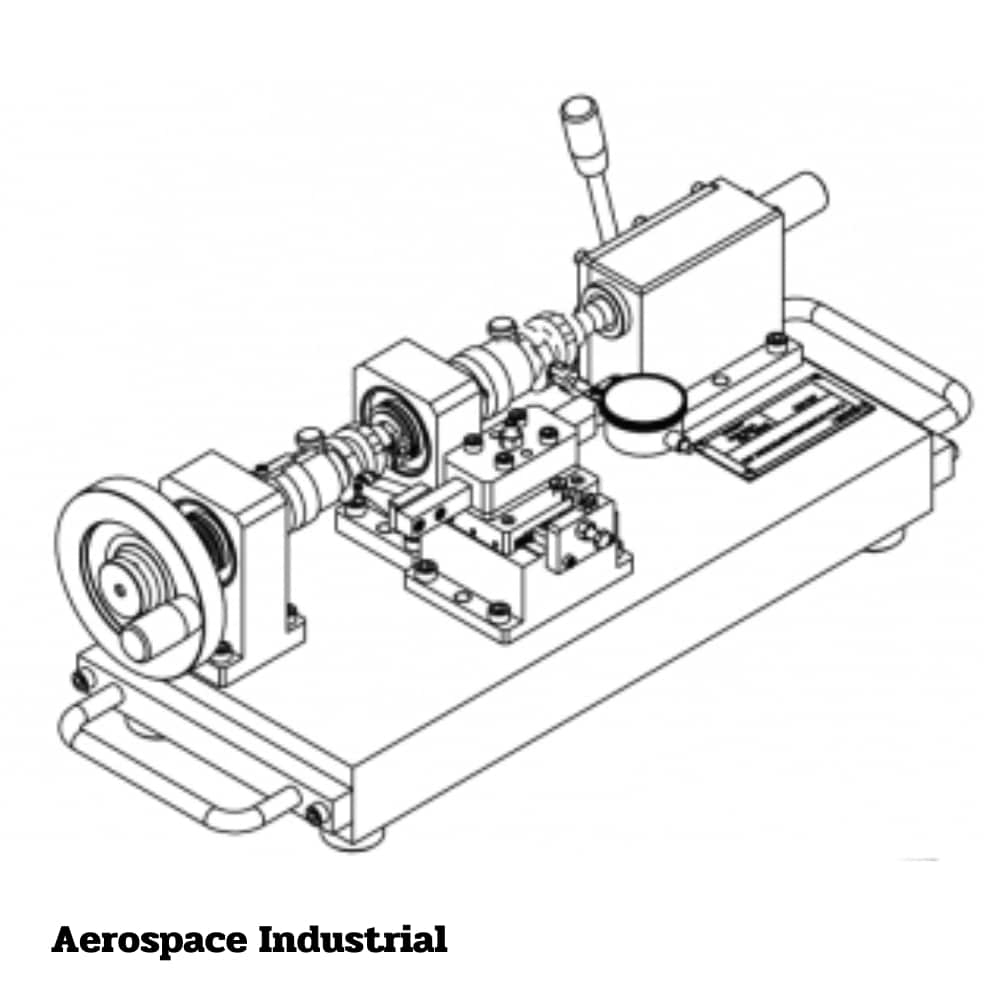

Measuring Jig

Measuring Jig: Precision Tools Shaping Quality Assurance

Introduction:

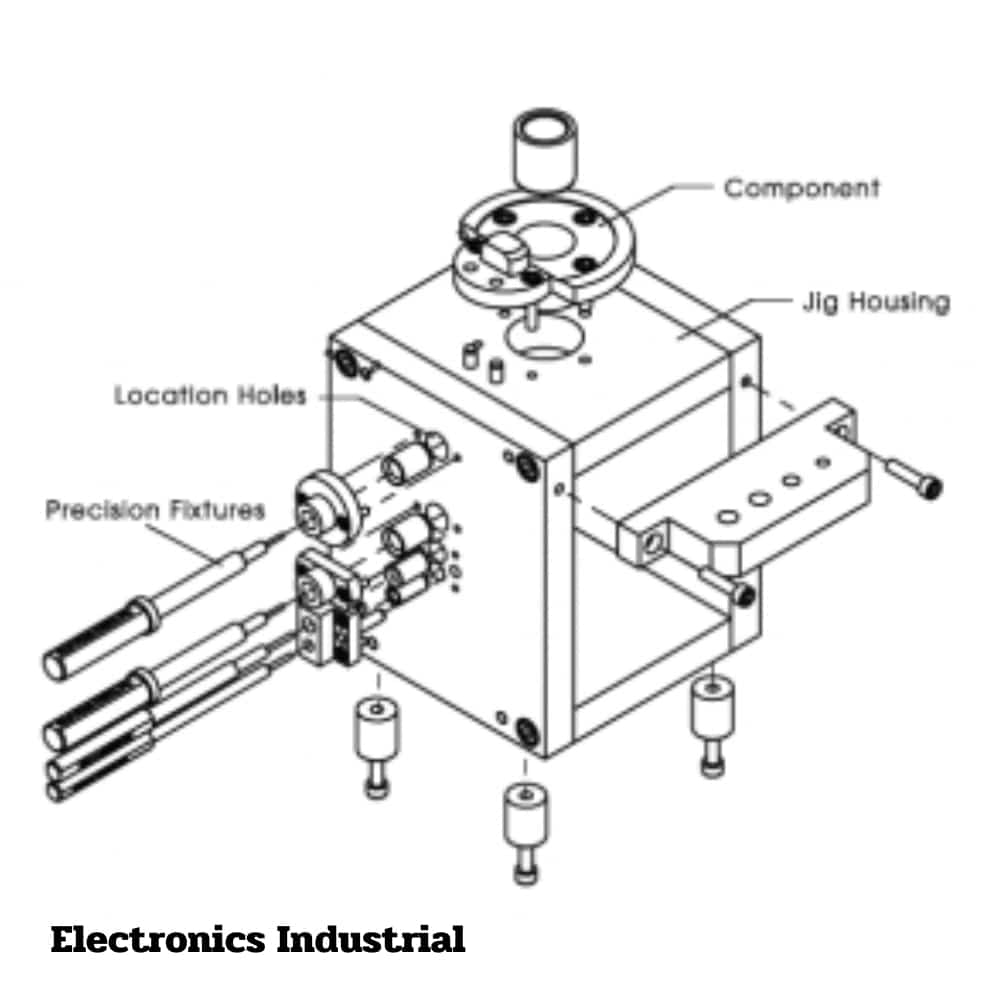

In the intricate world of manufacturing and precision engineering, measuring jigs emerge as essential tools, playing a pivotal role in quality assurance and ensuring the accuracy of machined components. This comprehensive exploration delves into the nuances of measuring jigs, examining their types, applications, design considerations, and the critical role they play in maintaining stringent quality standards across diverse industries.

Types of Measuring Jigs:

- Cylindrical Measuring Jigs:

- Specifically designed for measuring cylindrical objects, these jigs provide precise measurements of diameters, ensuring uniformity in manufacturing.

- Angular Measuring Jigs:

- Tailored for assessing angular dimensions, these jigs are crucial in verifying the accuracy of machined components with specific angular requirements.

- Height Measuring Jigs:

- Focused on measuring the height of components, these jigs ensure uniformity and adherence to specified tolerances in the vertical dimension.

- Depth Measuring Jigs:

- Used for accurately determining the depth of features, such as holes or recesses, contributing to the precision of machining operations.

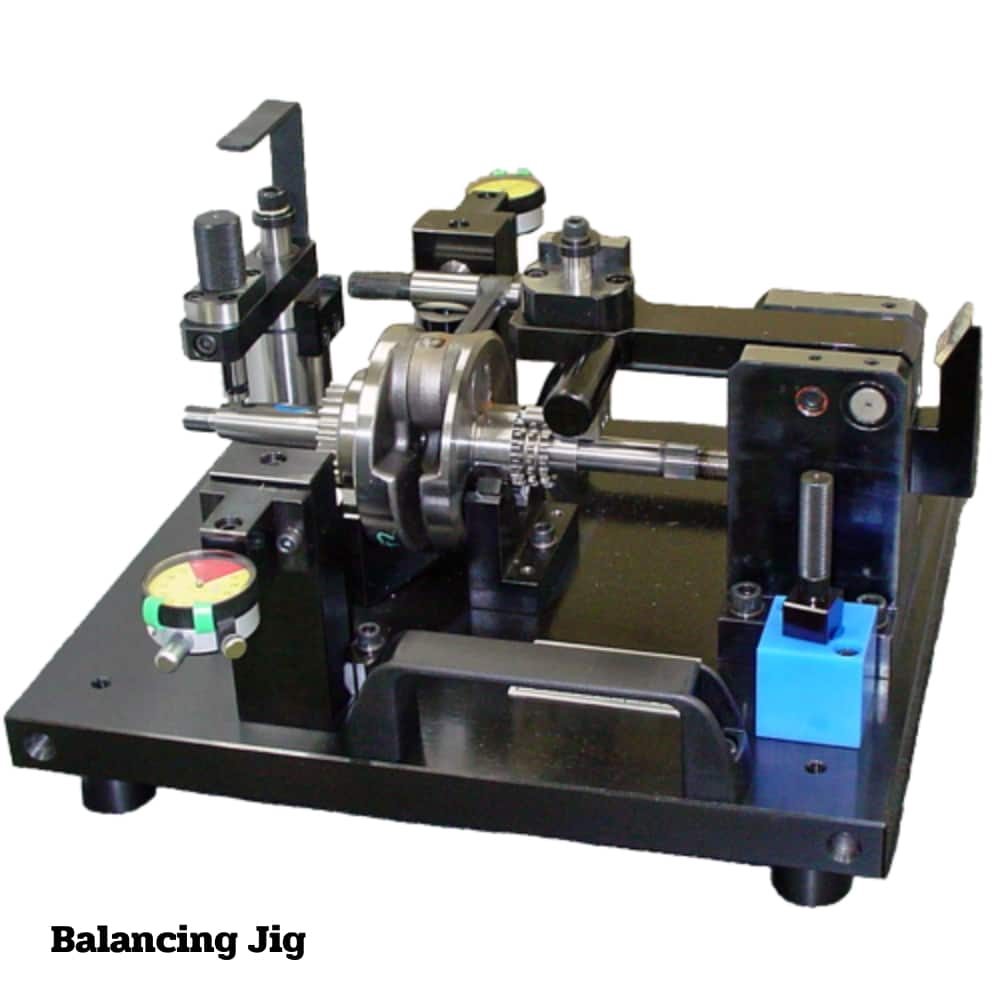

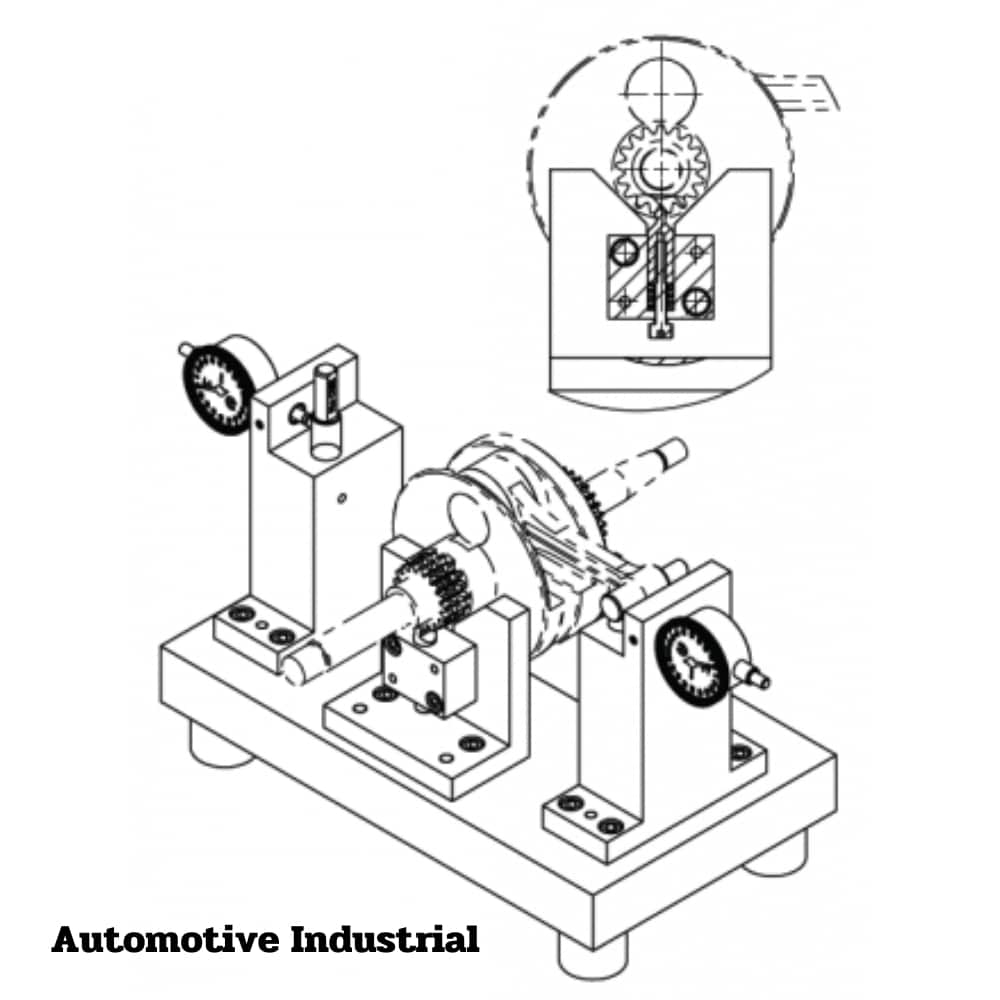

Applications of Measuring Jigs:

- Quality Control in Machining:

- Measuring jigs are integral to quality control processes, providing a reliable means of verifying the dimensions and tolerances of machined components.

- Tool Calibration:

- In calibration processes, measuring jigs are employed to ensure that machine tools are set up accurately, contributing to the precision of machining operations.

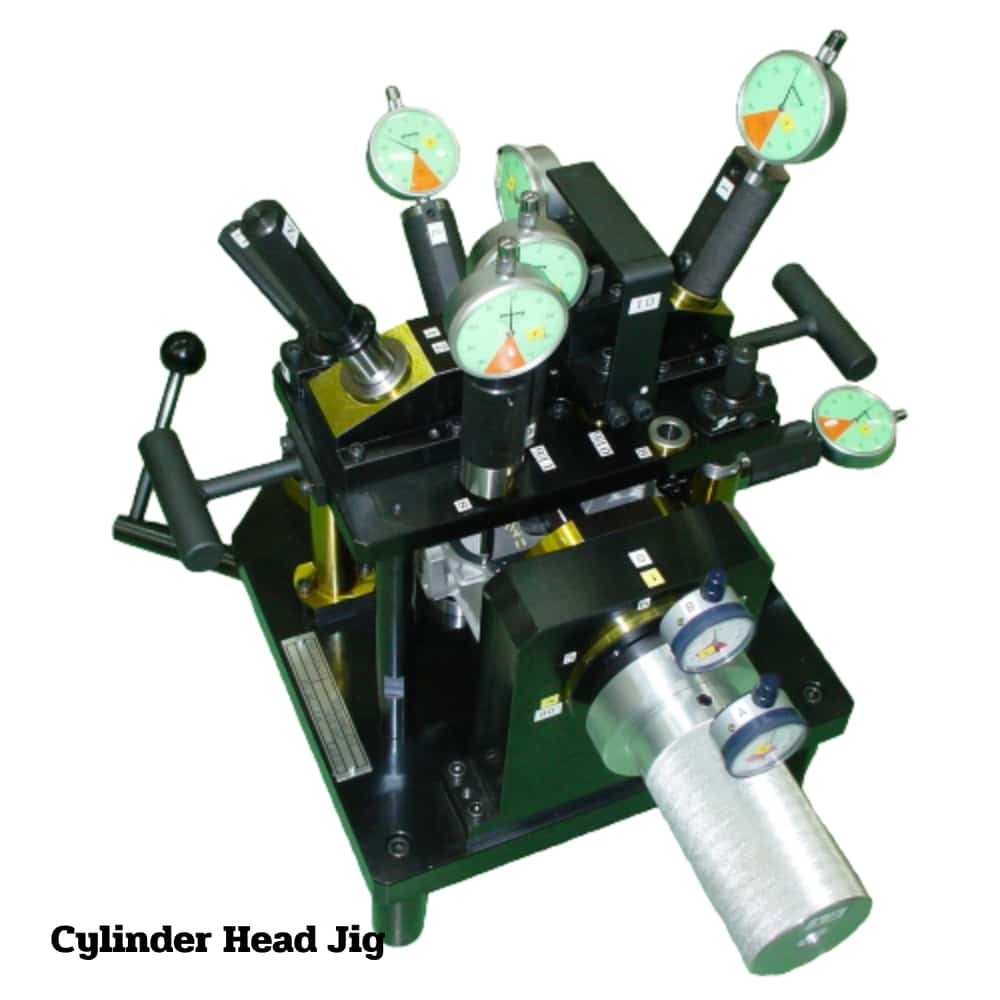

- Assembly Line Inspection:

- Measuring jigs find applications in assembly line inspection, where they help ensure that components fit together seamlessly and meet the required specifications.

- Prototype Development:

- During the prototyping phase, measuring jigs aid in assessing the accuracy of newly designed components, allowing for adjustments and improvements before mass production.

Design Considerations:

- Material Selection:

- Measuring jigs are often crafted from materials such as steel, aluminum, or high-quality alloys, balancing durability with the need for precision.

- Precision Machining:

- The manufacturing process for measuring jigs involves precision machining techniques, including CNC machining, to achieve the exact specifications required for accurate measurements.

- Surface Finish:

- A smooth and polished surface finish is imperative to prevent inaccuracies caused by irregularities on the surface of the measuring jig.

- Adjustability:

- Many measuring jigs are designed with adjustable components, allowing for versatility in accommodating various workpiece sizes and shapes.

Importance of Measuring Jigs in Quality Assurance:

- Dimensional Accuracy:

- Measuring jigs contribute to dimensional accuracy, ensuring that components meet the specified tolerances and conform to quality standards.

- Consistency in Production:

- By providing precise measurements, measuring jigs contribute to the consistency of production processes, minimizing variations in the manufactured components.

- Time and Cost Efficiency:

- The use of measuring jigs streamlines quality control processes, leading to increased efficiency and cost savings by reducing the need for rework or scrapping of defective components.

- Compliance with Standards:

- Measuring jigs play a crucial role in ensuring that manufactured components comply with industry standards and specifications, fostering regulatory compliance.

Conclusion:

In the intricate dance of precision engineering and manufacturing, measuring jigs take center stage, offering a meticulous means of ensuring the accuracy and quality of machined components. From height measurements to angular assessments, these tools serve as guardians of precision, underlining their indispensable role in diverse industries. As technology continues to advance, the evolution of measuring jigs remains intertwined with the ongoing pursuit of perfection in the world of metrology and manufacturing.

PROTOOL Distributor of high quality measuring tools, available in a variety of sizes and types to meet all your needs.You can inquire and order online with PROTOOL at

Line OA @protoolgauge , 02-123-3822 และ 085-660-5531

Follow more Protool at:

Facebook: Protool-Gauge เครื่องมือวัดละเอียด