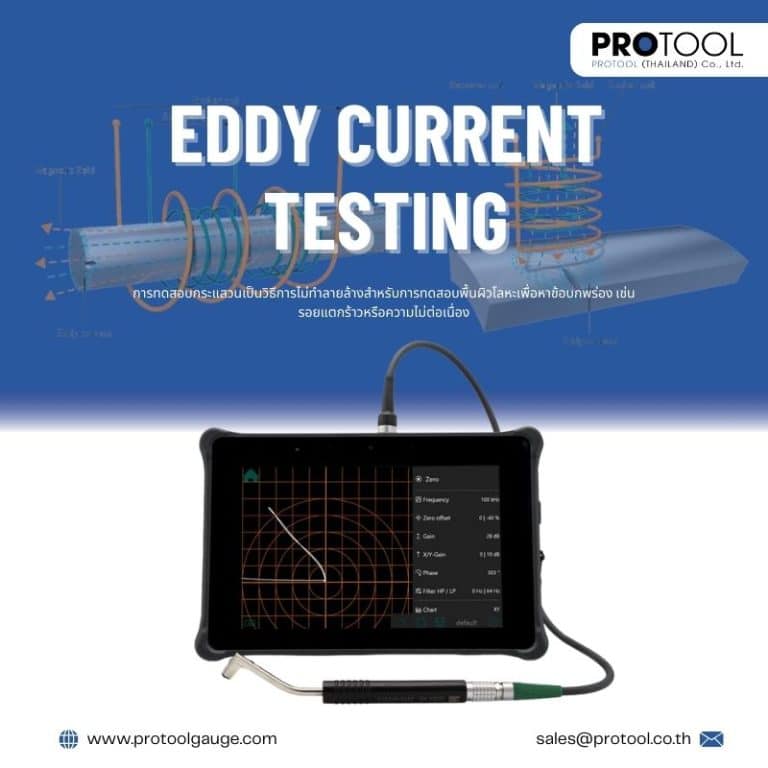

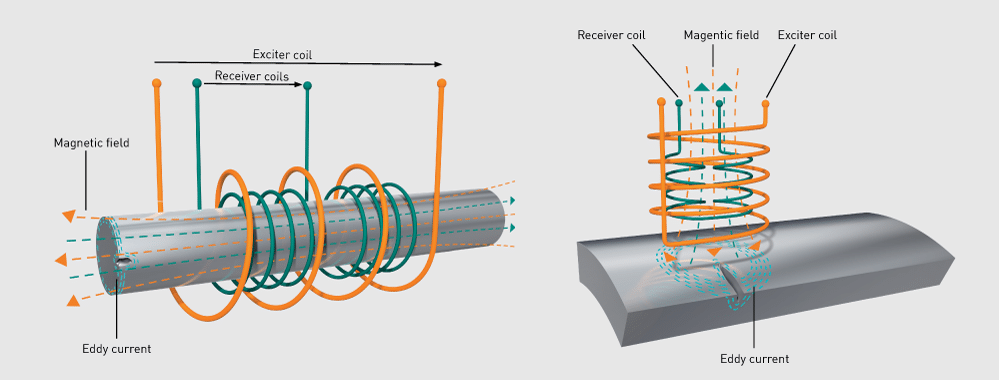

Eddy Current Testing (ECT) is a non-destructive testing (NDT) method that uses the principle of electromagnetic fields to examine the integrity of materials, especially metallic or conductive materials such as aluminum, steel and various alloys.

Working Principle

Eddy Current Testing is a non-destructive method for testing metal surfaces for defects such as cracks or discontinuities. Such surface defects have high-frequency electromagnetic interactions that allow them to be detected manually or automatically, depending on the need, and evaluated.

Defect resolutions of up to 30 µm can be achieved under suitable conditions. Testing is usually non-contact, so eddy current testing does not damage or contaminate the surface.

Modern sensors, electronic devices and software solutions offer a wide range of application and evaluation options for the metalworking and metal fabrication industries, including mobile applications in maintenance testing.

The extremely low media consumption and maintenance costs of eddy current testing make it one of the most economical and environmentally friendly non-destructive testing methods available, and is therefore widely used in 100% of manufacturing processes. In addition, the high testing speed and automated testing mean that the production process is not disrupted.

Eddy current method in semi-finished product and component testing In the field of semi-finished product and component testing, the frequency range is up to 10 MHz and is used to test metals for surface defects. A variety of differential coils are commonly used for this test. Standard and customized sensors are used.

Semi-finished products, such as wires, rods and tubes, are inspected for transverse cracks and pitting defects using a surrounding coil, while the surface of the semi-finished product is tested for longitudinal defects using a rotating probe. A fixed probe can also be used to test critical points on the component. The selection of the appropriate sensor always depends on the test task, allowing for very detailed defect testing.

Eddy current method in metal detection

In metal detection, eddy current testing is used to generate an electromagnetic field with one or two frequencies, which can be used to detect even the smallest amount of hidden metal (e.g. iron, steel, aluminum, copper, gold, silver).

The sensor emits an electromagnetic field to detect metallic objects using an active sensor, which induces eddy currents in the object being detected, creating a secondary electromagnetic field that is detected by the sensor and used for evaluation.

PROTOOL ผู้จัดจำหน่ายเครื่องมือวัดคุณภาพสูง มีให้เลือกหลากหลายขนาด หลากหลายประเภท ตอบโจทย์ทุกความต้องการของคุณ สามารถสั่งออนไลน์กับ PROTOOL ได้เลยที่

Line OA @protoolgauge , 02-123-3822 และ 085-660-5531 เราพร้อมจัดส่งทั่วประเทศไทย

ติดตาม Protool เพิ่มเติมได้ที่ :