Go-NoGo Gauges

Go-NoGos, also known as plug gauges, are basic precision instruments used in manufacturing and quality control processes. These essential tools play a crucial role in ensuring that machined parts and components meet precise tolerances and strict industry standards. In this in-depth guide, we explore the world of gauges, their types, applications, and maintenance practices, providing valuable insights for professionals and enthusiasts in the field.

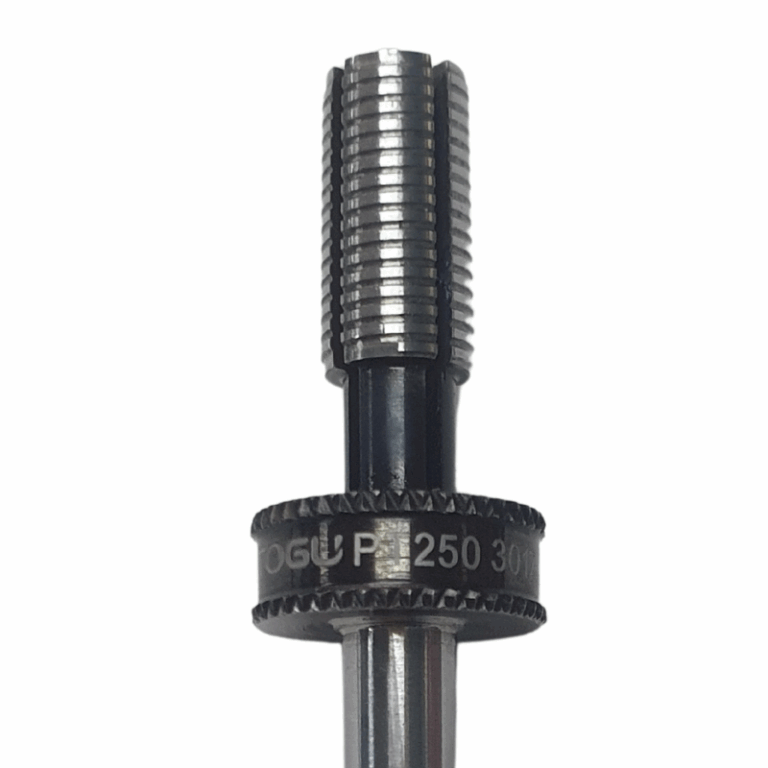

Understanding Gauges A simple yet highly effective device designed to assess whether a part’s dimensions are within tolerance. They consist of two ends: a “go” end and a “no-go” end. These gauges are used to verify the accuracy of holes and external features in mechanical components. The “go” end represents the upper tolerance limit, and if it fits properly in the tested part, the part is considered within tolerance and is accepted for use. Conversely, the “no-go” end represents the lower tolerance limit, and if it fits properly in the part, the part is considered out of tolerance and is rejected. They are essential in quality control and warranty processes to ensure that manufactured components meet specified standards.

Types of Gauges

There are several types, each designed for specific applications:

– Plug Gauge: Used to assess the internal dimensions of a hole. To ensure that the tolerance is within specified limits, plug gauges are essential for checking the precise size of holes in a variety of applications.

– Ring Gauge: Ring gauges are used to measure the external dimensions of cylindrical parts such as shafts, bolts and fasteners, ensuring that the threads and external dimensions are within specified tolerances.

– Snap Gauges: Snap gauges are versatile instruments that can be used for both internal and external measurements. They are often designed to measure many different features in a single operation, making them an effective tool for quality control.

– Thread Gauge: Used to check the dimensions of both internal and external threads.

Applications

Automotive Industry

In automotive manufacturing, Go-NoGo gauges are used to check the dimensions of engine components such as cylinders, valve trains and bushings, ensuring that engines operate efficiently and reliably.

Aerospace Industry

Aerospace components require the highest level of accuracy. Go-NoGo gauges are used to check the dimensions of critical holes, threads and features in aircraft components such as turbine blades, engine parts and fasteners.

Medical Devices

The manufacturing of medical devices and instruments, such as bone grafts or surgical instruments, requires very high levels of accuracy. Go-NoGo gauges ensure that holes, threads and features meet strict specifications, ensuring patient safety.

General Manufacturing

In general manufacturing, These gauges are used to inspect a variety of components, from bolts and nuts to hydraulic joints and bearings, helping to maintain the overall quality and reliability of products across a variety of industries.

Maintenance of Gauges

Proper care and maintenance are essential to keep gauges in optimal working condition, ensuring they provide reliable and accurate measurements over time. Some important maintenance practices include:

Regular Calibration: Schedule periodic calibrations by a certified body to verify the accuracy of your gauge. Calibration ensures that your gauges provide reliable measurements in line with industry standards.

Cleaning: Keeping your gauges clean and free of contamination is essential. Use a lint-free cloth, appropriate cleaning materials, and compressed air to remove debris and dirt that could affect the measurement.

Storage: Storing them in a protective case when not in use helps prevent damage to the measuring surface and maintains the gauge’s accuracy. Proper storage also helps protect the gauge from environmental factors that could affect the gauge’s accuracy.

Handling: Handle with care to avoid accidental damage to the measuring surface. Improper handling, dropping, or applying excessive force can affect their accuracy and longevity.

Conclusion

Go-NoGos gauges are essential tools in manufacturing and quality control, contributing to the production of high-quality components and products. Their simplicity and efficiency make them a cornerstone of quality assurance, ensuring that parts meet the highest standards of quality. By understanding the types of Go-NoGos gauges, their applications, and following proper maintenance practices, professionals and enthusiasts can rely on these precision instruments to provide consistently accurate measurements and maintain the integrity of their products and processes. Whether you operate in the automotive, aerospace, medical, or general manufacturing industries, Go-NoGos gauges are your ally in achieving accuracy and quality assurance.

PROTOOL ผู้จัดจำหน่ายเครื่องมือวัดคุณภาพสูง มีให้เลือกหลากหลายขนาด หลากหลายประเภท ตอบโจทย์ทุกความต้องการของคุณ

สามารถสอบถามและสั่งซื้อออนไลน์กับ PROTOOL ได้เลยที่ Line OA @protoolgauge , 02-123-3822 และ 085-660-5531

ติดตาม Protool เพิ่มเติมได้ที่ :