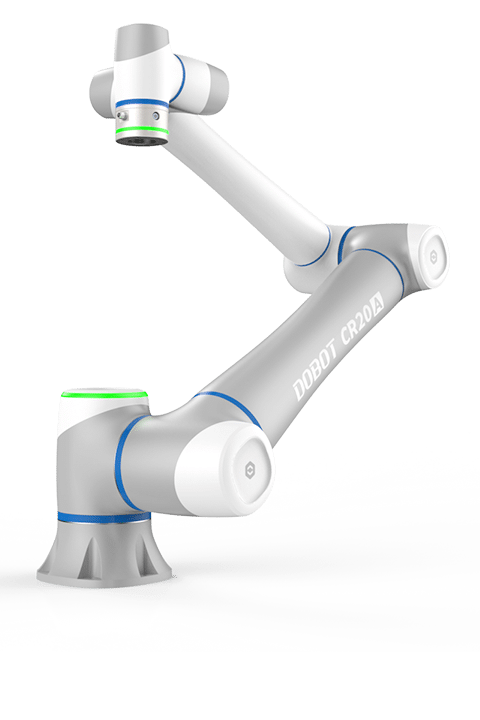

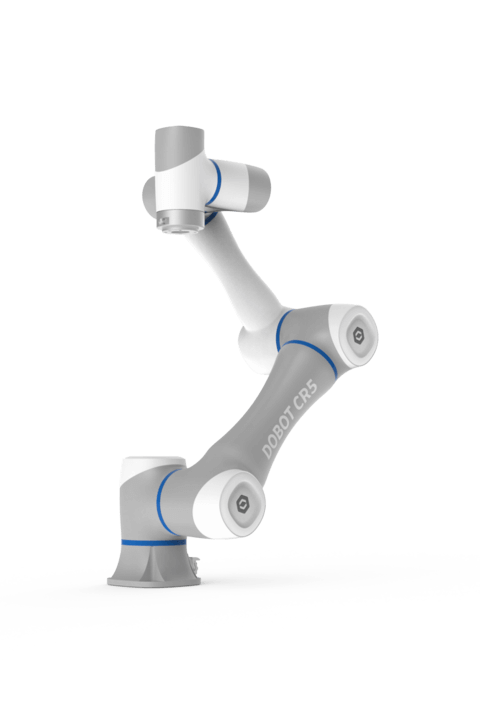

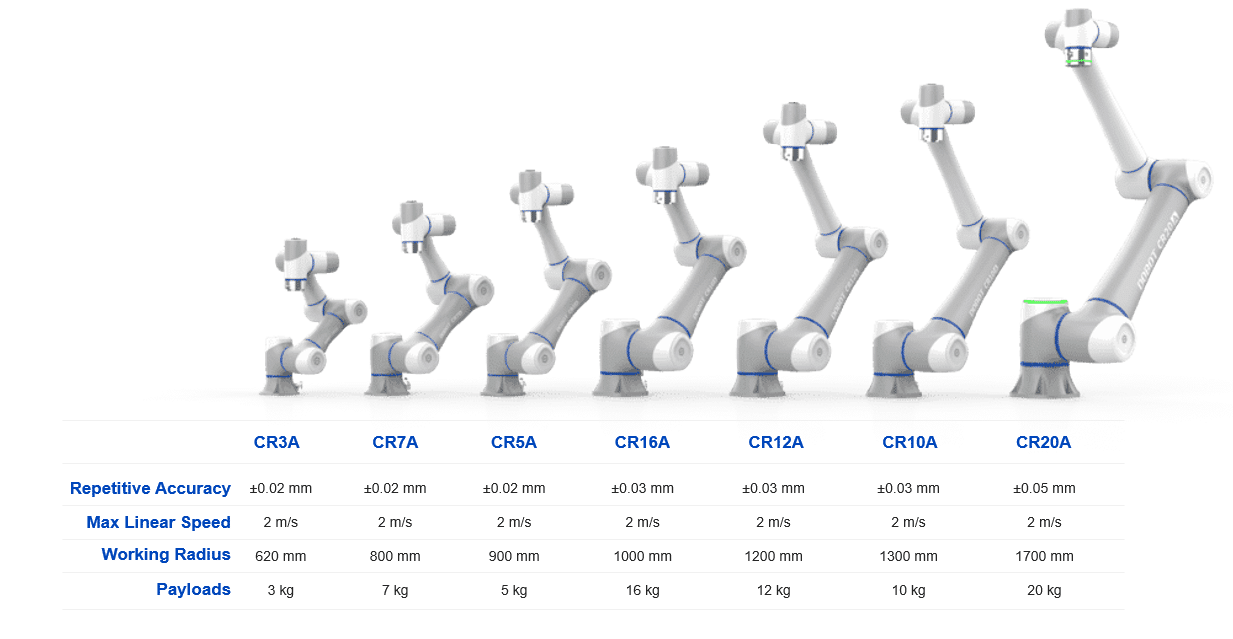

CRA Cobot Series

CRA Cobot Series

CRA Cobot Series

The new collaborative robot CRA Cobot Series features high-performance integrated joints, resulting in a 25% increase in cycle time and unprecedented efficiency. The new control cabinet and DobotStudio Pro system software comprehensively enhance safety, stability and scalability, and take human-machine collaboration to the next level.

Safety is essential in human-machine collaboration. The best solution is a safety mechanism that maintains efficiency while prioritizing safety. SafeSkin, the industry’s only mass-produced safety skin, features non-contact inspection and collision avoidance capabilities. This innovative technology enables collaborative robots to operate at an impressive speed of 1 m/s, which is four times faster than the international standard. Unlike traditional methods that require robots to slow down to avoid collisions, SafeSkin combines efficiency and safety.

Building on the powerful, flexible and user-friendly CRA Series and enhanced with SafeSkin, the CRAS Series helps you achieve more efficient and safe human-machine collaborative manufacturing.

Advanced

- High efficiency – Motion cycle time is improved by 25%

- Safety – Electromagnetic brake with more than 20 levels of safety design

- Multiple interface expansion capability

- Flexibility – Multi-terminal operation and intelligent interactive interface

Features

- SafeSkin – Innovative Pre-collision Sensing Technology

Dobot’s exclusive technology for safer operations. - Reliable and Efficient

High performance harmonic drive reducers improve cycle time by 25%. Improved anti-vibration algorithm, optimal DH parameters compensation, and TrueMotion algorithm achieve 0.2 – 0.4 mm trajectory accuracy during complex movement. - Safe & Reassuring Collaboration

It is equipped with responsive electromagnetic brakes for safety. When there is a power outage, the brakes are engaged automatically within 18 ms, with a fall of less than 1 mm. It also supports the function of virtual boundaries, setting safety borders freely, with alert when borders are exceeded, machine deceleration and machine halt. Its end tool real-time payload detection ensures the safety of production, upgraded to 10 I/O ports to satisfy the safety requirements of external devices. - New Interface for Easy Operation

The 4th generation of DobotStudioPro has a good layout, making operation easy and efficient. The newly added environment simulation function allows calibration to be more straight forward. There are three programming methods: graphical programming, script programming and trajectory replay which can be controlled by PC computer, tablet, smartphone and teaching pendant. - 2.5D Vision for Accurate Grabbing

Integrates 5-megapixel camera and LED light source with Dobot self-developed 2.5D spatial compensation technology, for applications such as grabbing slanted surfaces on objects and assembly for fixed positions and also transportation of AMMR robots and loading and unloading scenarios. The VX500 Smart Camera works with visualizable operation software, saves the hassle of development while being easy to deploy. - High Expandability

2 industrial grade Ethernet ports. Supports Modbus Ethernet/IP and Profinet communication. 24 I/O ports allow more external devices to be used.

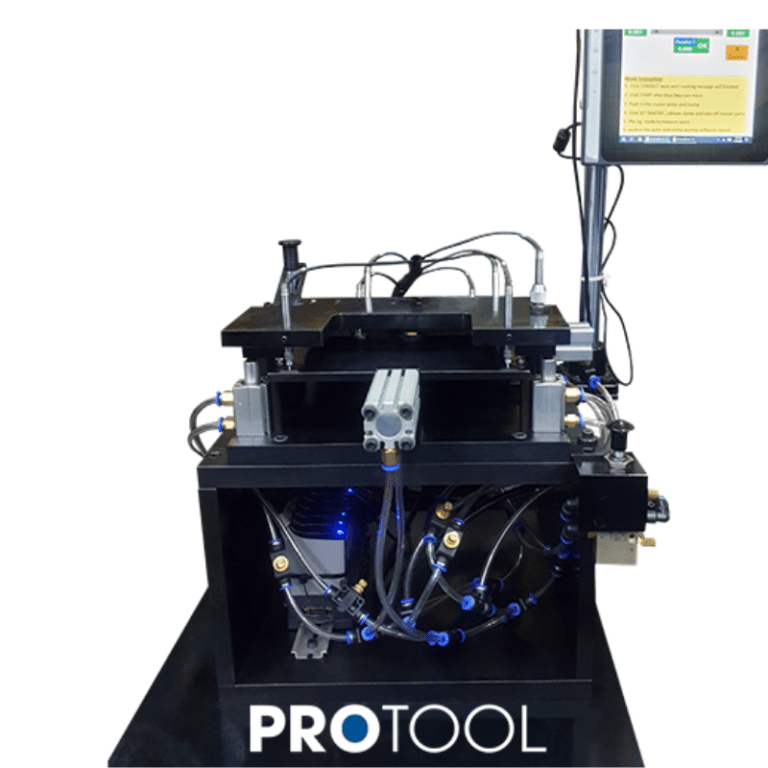

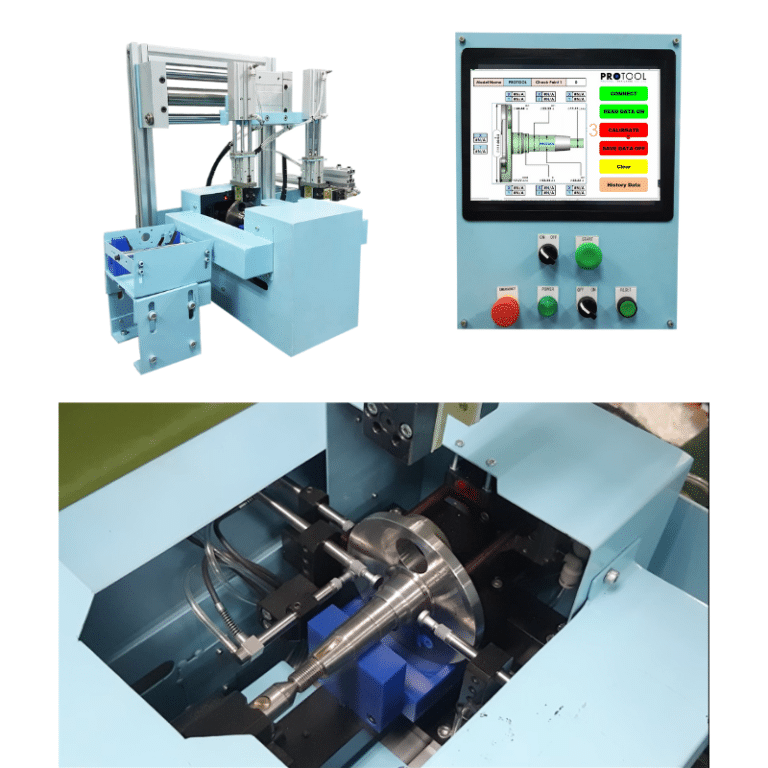

Distributor of high quality measuring tools, available in a variety of sizes and types to meet all your needs.

You can inquire and order online with PROTOOL at Line OA @protoolgauge , 02-123-3822 และ 085-660-5531

ติดตาม Protool เพิ่มเติมได้ที่ :