In today’s rapidly advancing industrial production and measurement technologies, the Probe has become a crucial tool for ensuring precise and efficient measurement and inspection. This article will discuss the various types of probes, their industrial applications, and the benefits of using them.

What is a Probe?

A probe is a device used to measure and inspect parameters in various industrial settings. Typically, probes are designed with a sensing head that touches or comes close to the workpiece or area to be measured, capturing data that is then sent to a measurement system or computer for analysis.

Types of Probes:

- Digital Probe:

- Uses digital technology for measurement, offering high accuracy. It can be easily connected to a computer system for data analysis and processing.

- Analogue Probe:

- Uses analog signals for measurement. While it offers lower precision compared to digital probes, it is still useful for tasks that do not require extremely high resolution.

- LVDT (Linear Variable Differential Transformer) Probe:

- Uses electromagnetic induction technology to measure linear displacement. It offers high precision and stability, making it ideal for tasks requiring detailed measurements.

Industrial Applications of Probes:

- Quality control in manufacturing: Probes are used to measure the size and shape of parts to ensure they meet the required quality and standards.

- Laboratory research and development: Probes are used to measure and test various properties of materials and products.

- Automated systems: Probes are integrated into automated production systems to provide real-time measurement and control, improving efficiency.

- Machine and equipment inspection: Probes can be used to measure the movement and performance of machinery to prevent damage or interruptions in the production process.

Advantages of Using Probes:

- High accuracy: Probes can deliver precise measurements, ensuring reliable results.

- Fast response: They provide quick feedback, which is essential in continuous production processes.

- Durability: Probes are designed to withstand harsh working conditions, such as dust, humidity, and vibrations.

- Versatility: With various types and models available, probes can be tailored to different measurement needs.

Probes are essential in the industry as they contribute to improved production quality, reduced errors, and increased operational efficiency. Selecting the right probe for specific measurement tasks can significantly enhance accuracy and productivity in industrial processes.

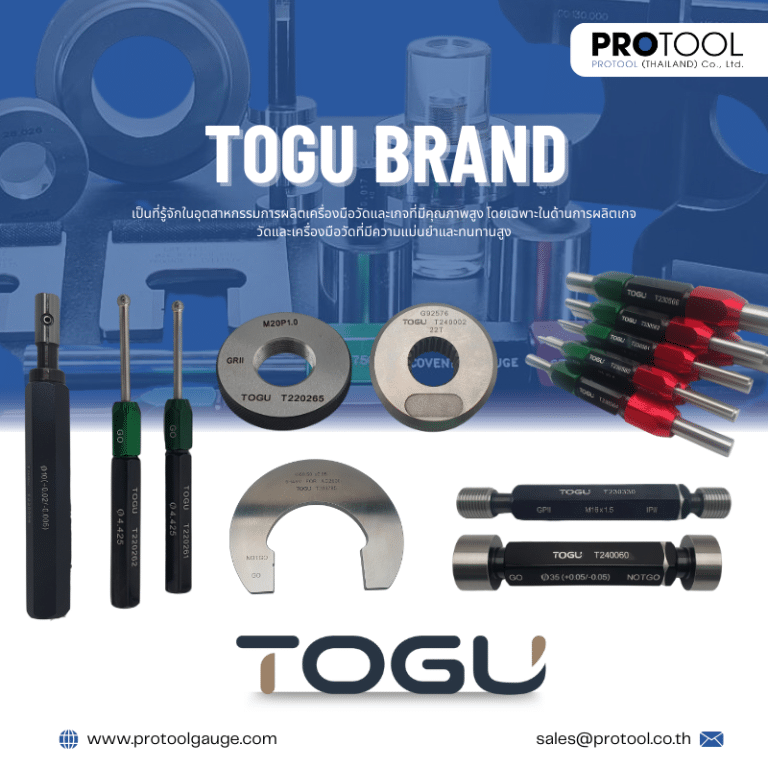

PROTOOL offers a wide range of high-quality probes and measuring tools. You can contact and place orders through Line OA @protoolgauge or by calling 02-123-3822 and 085-660-5531.

Follow Protool for more updates:

- Facebook: Protool-Gauge Measuring Tools

- YouTube: Protool Thailand