How to read micrometer

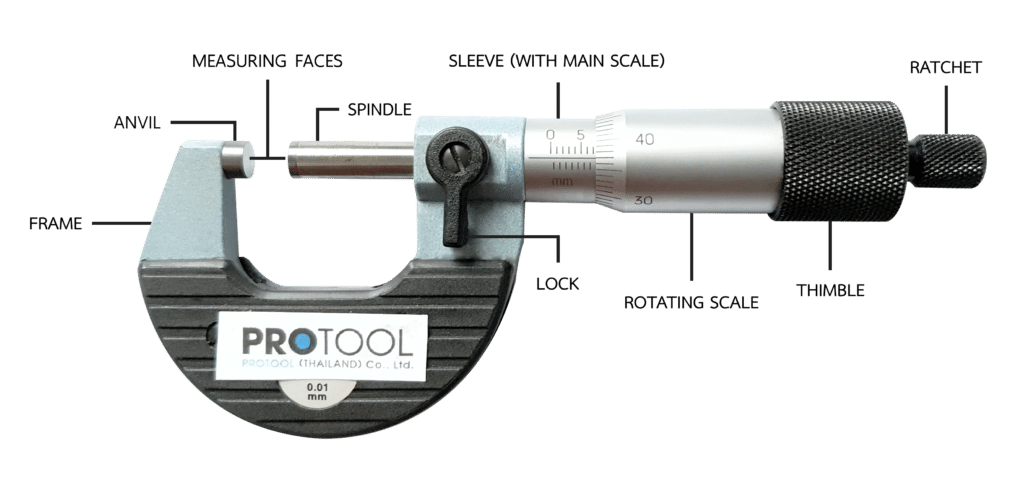

Micrometer is a sliding scale precision measuring instrument that can measure workpiece dimensions in terms of length, width, difference and depth. Often used in the machine tool industry and the automotive industry, etc. The working principle of the micrometer is based on the movement of the screw with the integral mouthpiece, measuring sleeve, scale rod and sliding impact rotary head, which is durable, small in size, compact in use. It is easy to operate. It can measure objects with a size of 0.01 mm. This make it possible to measure and read detail with high accuracy. A micrometer is an external micrometer and depth measurement. Each type of micrometer has its characteristics and methods of use.

STEP 1 Check the micrometer before use.

To obtain accurate results with a micrometer, the user must select the appropriate workpiece type. Check the use of micron and the correct tracking procedure before cleaning the workpiece. Rotate so that the micron measuring axis is expanded to a larger size, and then the spindle contacts the target. The line is close to a target by a rotating axis, about 1-2 mm. The measured value of the rotation will then be read.

STEP 2 Look at the main scale.

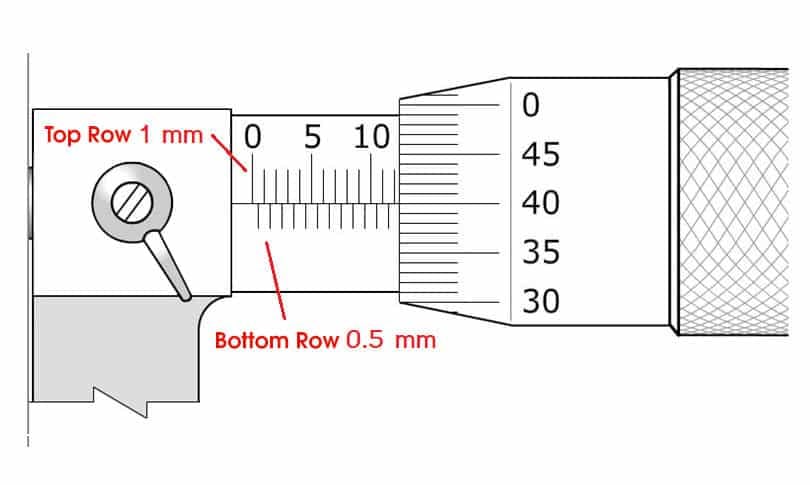

The top row represents all millimeter gradients. The circumference of the thimble is divided into 50 equal divisions, 1 mm.

The bottom row means 0.5 mm each turn of the thimble will make the spool ½ mm (0.5 mm).

STEP 3 Method of reading Micrometer

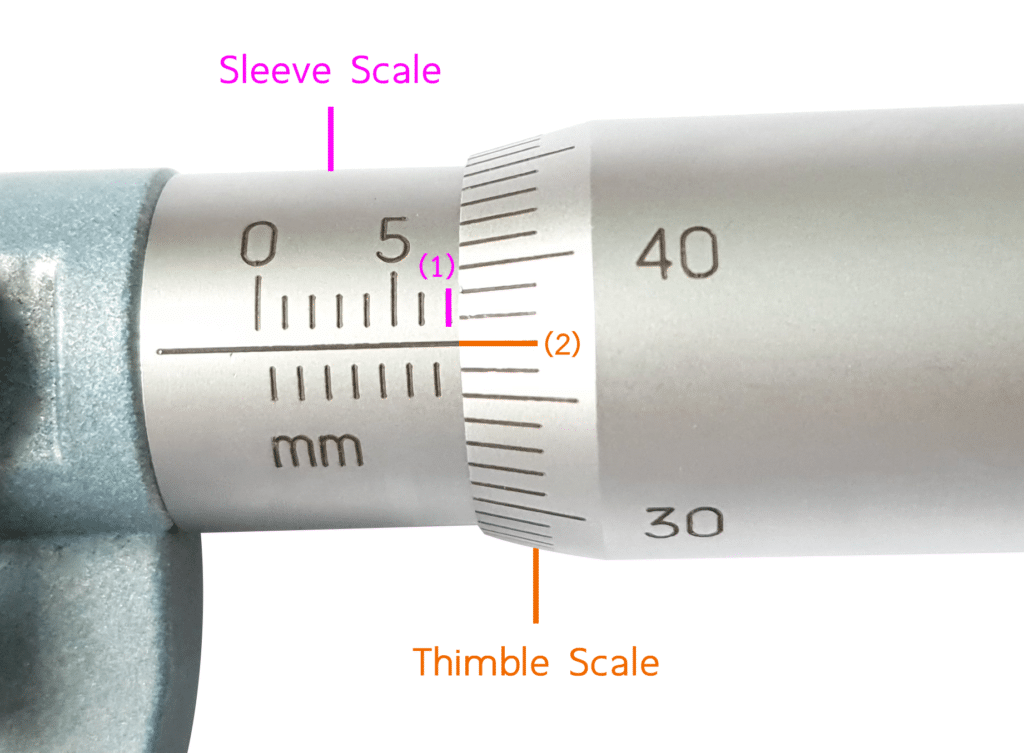

Micrometer, resolution 0.01 mm.

(1) Sleeve Scale 7 mm.

(2) Thimble Scale 0.37 mm.

Read micrometer 7.37 mm.

Read the measurement result at the master scale (Sleeve scale) Notice where the edge of the Thimble scale corresponds to the range of the main scale. From the figure, it can be seen that the edge The dial scale corresponds to the main scale. In the range 7 mm to 8 mm, readings at 7.00 mm on the main scale are readable.

Read the measurement result on the rotary scale (Thimble scale) See the position of the rotating scale to see if the scale corresponds to the center line of the main scale. From the figure, can be seen that 37th rotation scale corresponds to the center of the main scale exactly. can read the value of the rotary scale By multiplying the resolution value of the instrument, the readable rotary scale line is 37 x scale, 0.01 mm resolution equals 0.37 mm. The rotary scale is 7.00 mm. 0.37 mm is equal to 7.37 mm.