A Taper Gauge is a tool used to measure the taper or angle of bores or slots in various parts that require precision measurement. This article will present information about how it works, different types, and its industrial applications.

What is a Taper Gauge?

A taper gauge is a tool designed to measure the taper or angle of bores or slots. It generally comes in the form of a metal strip that gradually narrows from one end to the other, or as a digital gauge that displays the taper or angle measurements.

Types:

- Metal Strip Taper Gauge:

- Description: A metal strip that gradually tapers.

- Usage: Insert into the bore or slot to be measured and read the value from the scale on the strip.

- Advantage: Easy to use and durable.

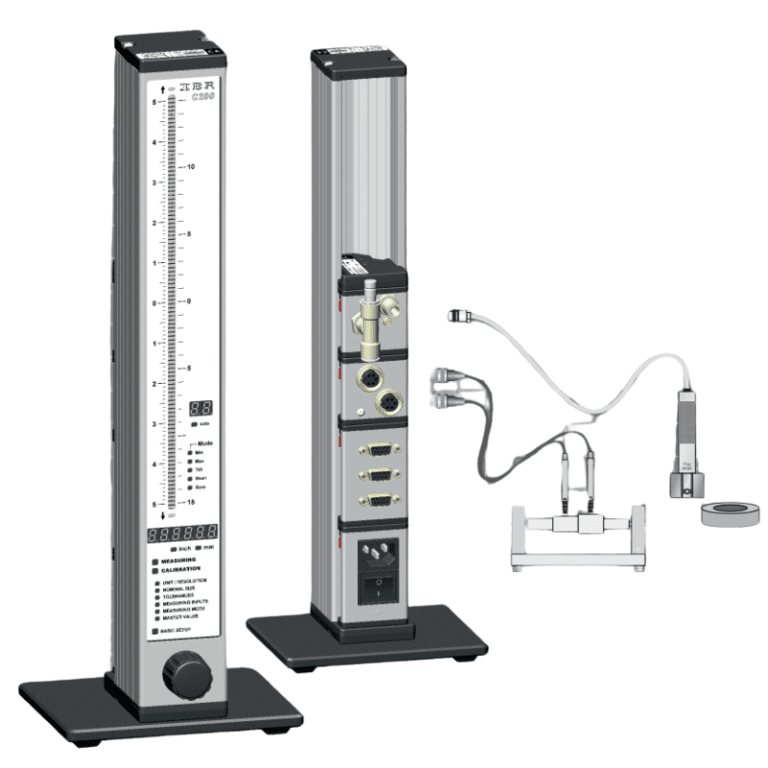

- Digital Taper Gauge:

- Description: Equipped with a digital display that shows the taper or angle measurements.

- Usage: Provides precise taper measurements and easy-to-read values.

- Advantage: High accuracy and convenience.

- Dial Taper Gauge:

- Description: Features a dial that displays the taper measurement.

- Usage: Insert or rotate it into the bore and read the value from the dial.

- Advantage: Easy and quick to read.

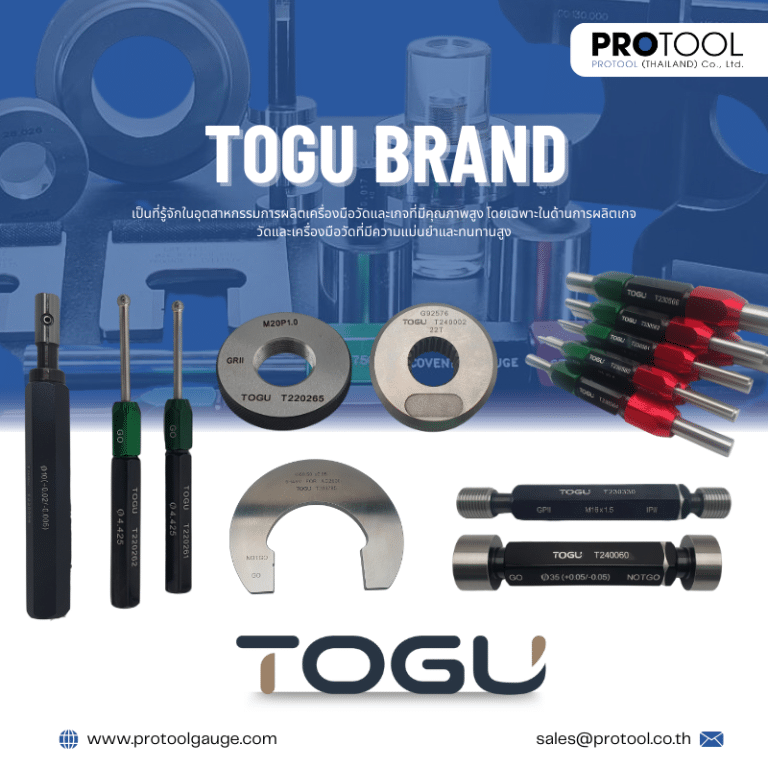

- Plug Taper Gauge:

- Description: A tapered metal rod, often used to inspect specific bores with precise taper.

- Usage: Insert into the bore to ensure it meets the desired size and taper specifications.

Working Principle:

Taper gauges work by being inserted into the bore or slot where taper measurement is needed. Once inserted, the user reads the taper value from the scale, digital display, or dial on the gauge.

Applications:

- Manufacturing Process: Used to measure the taper of bores in parts to ensure they meet standard size and shape requirements.

- Maintenance: Helps measure angles and tapers in bores during machine and equipment maintenance to ensure correct part dimensions.

- Laboratory Quality Inspection: In research and development labs, it helps verify product dimensions and taper to ensure product quality and for further development.

Advantages:

- High Accuracy: Capable of measuring taper values precisely, providing reliable results.

- Ease of Use: Designed for easy handling, allowing users to take measurements conveniently and quickly.

- Quick Response: The tool provides fast measurements, making it ideal for continuous measurement during production.

- Durability: Designed to withstand harsh working conditions such as dust, moisture, and vibrations.

PROTOOL – Distributor of High-Quality Measuring Tools:

PROTOOL offers a wide selection of taper gauges in various sizes and types, meeting all your measurement needs. You can inquire and order online from PROTOOL via Line OA @protoolgauge, 02-123-3822, and 085-660-5531.

Follow Protool for more:

- Facebook: Protool-Gauge เครื่องมือวัดละเอียด

- YouTube: Protool Thailand